By Marco Mezger, EVP & COO at memory specialist Neumonda, President MEMPHIS Electronic

Recently, we said Farewell to Gordon Moore, who shaped the semiconductor industry like no other. His observation that the number of transistors doubles approximately every two years is known as Moore’s Law and made him a legend in the industry. Because even today, almost 60 years later, it still holds true, and semiconductors have transformed our lives in a way that even Gordon Moore wouldn’t have thought possible.

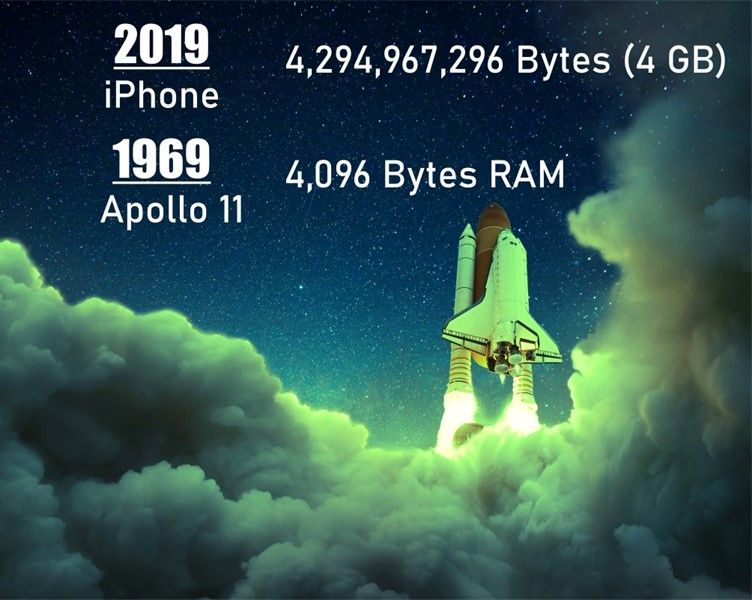

Memory technologies are a prime example, as they not only increased the storage capacity and performance of electronic devices but have also opened doors to new possibilities. DRAM memory was invented 55 years ago and has remained a vital technology enabler until today. If you think of it, in 1969 Apollo 11 flew to the moon with only 4,096 Byte of DRAM in its computer, the first embedded computer by the way. 50 years later iPhone 11 had 4GB RAM. That is more than a million times the RAM of the Apollo computer! Moore's Law has driven the reduction in the size of these memory cells, allowing for increased storage capacity in smaller form factors.

Another of Moore’s great accomplishments is his support of research and development, fostering technology innovations and collaboration within the industry. This has helped to keep pace with continuous advancements even though many predicted the end of Moore’s Law several decades ago. Because every time the physical limitations seemed impossible to overcome, new materials, and manufacturing technologies opened the door for higher density on a smaller footprint.

Miniaturization not only led to a more complex semiconductor manufacturing process that operates at the limit of physics and costs, but the applications are also getting smaller, more varied and more demanding. Memory is a commodity that no modern application can do without. And while they might look the same on paper, there are nuances in the manufacturing process that can have a negative impact on thermal management and signal integrity depending on the environment they are used in.

Therefore, testing is more critical than ever before. But due to the size, complexity and costs of the equipment, only few companies can afford to implement test capabilities. And those who do, need to test high volumes to recoup the investment, which means that test times need to be short and clear only the main requirements of the most common applications. Niche requirements cannot be served.

However, there are errors in DRAM technology that only arise in longer run times, like for example, variable retention time induced fails or signal integrity issues. Testing for several hours or even days can eliminate the risk of costly recalls of failing memories once they are widely deployed.

One of the companies tackling these pain points is Neumonda Technology which was founded in 2021 and has since worked on the development of a new lightweight test board for industrial uses and environments. Its new test board simulates the application that a DRAM will be used in and is able to predict much more accurately than other technologies in the market how well a memory will do in that target system. This new approach significantly reduces the investment requirements for long-term testing and provides system and application-tailored testing for customer needs.

It’s ideas like these that are needed to increase the manufacturing yield and be more cost-efficient in bringing products to market. The semiconductor industry is a bloody business. With continuous research and development, fostering of technology innovations and collaboration in the industry, companies will be able to adapt and thrive in this volatile market. And ultimately prove that Moore’s Law lives on.